But what goes into the production process of a Modern Vertical Shoe Rack For Front Door? From design to material selection and final assembly, creating a high-quality shoe rack involves several steps. This article takes a deep dive into the production process of this essential home accessory, highlighting each phase and the attention to detail that makes these racks both functional and stylish.

The production of a Modern Vertical Shoe Rack For Front Door starts with a clear design concept. The main goal of these racks is to efficiently store shoes while taking up minimal space. As the name suggests, these racks are designed to be vertical, meaning they maximize vertical space rather than spreading out horizontally. This design is good for small entryways or apartments where every inch counts.

Designers focus on the functional requirements of the Modern Vertical Shoe Rack For Front Door. The ideal product should accommodate a variety of shoe types, from flats to boots to sneakers. The vertical design should allow shoes to be stored in a way that prevents overcrowding, making it easier to access each pair. Another important consideration is the rack's footprint. It should be narrow enough to fit in tight spaces while still offering adequate storage capacity.

A well-thought-out design will also account for the aesthetic appeal of the Modern Vertical Shoe Rack For Front Door. These racks should blend seamlessly with a range of home décor styles, from contemporary and minimalist to more rustic or industrial looks. Materials and finishes are carefully chosen to ensure the final product is not only practical but also visually pleasing.

After the design is finalized, the next step is selecting the appropriate materials for the Modern Vertical Shoe Rack For Front Door. The material choice is crucial for the durability, strength, and visual appeal of the rack.

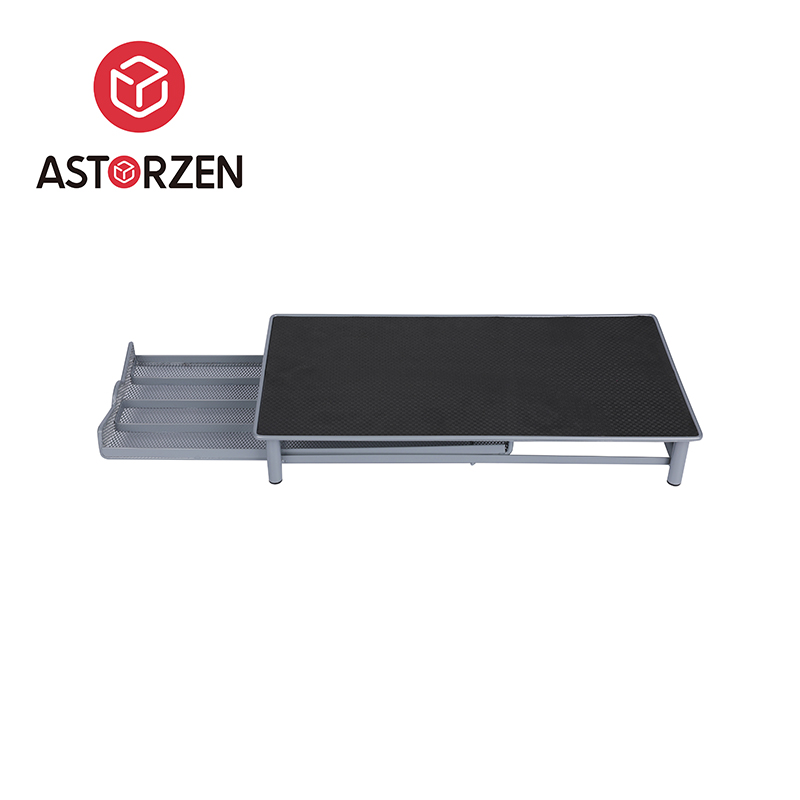

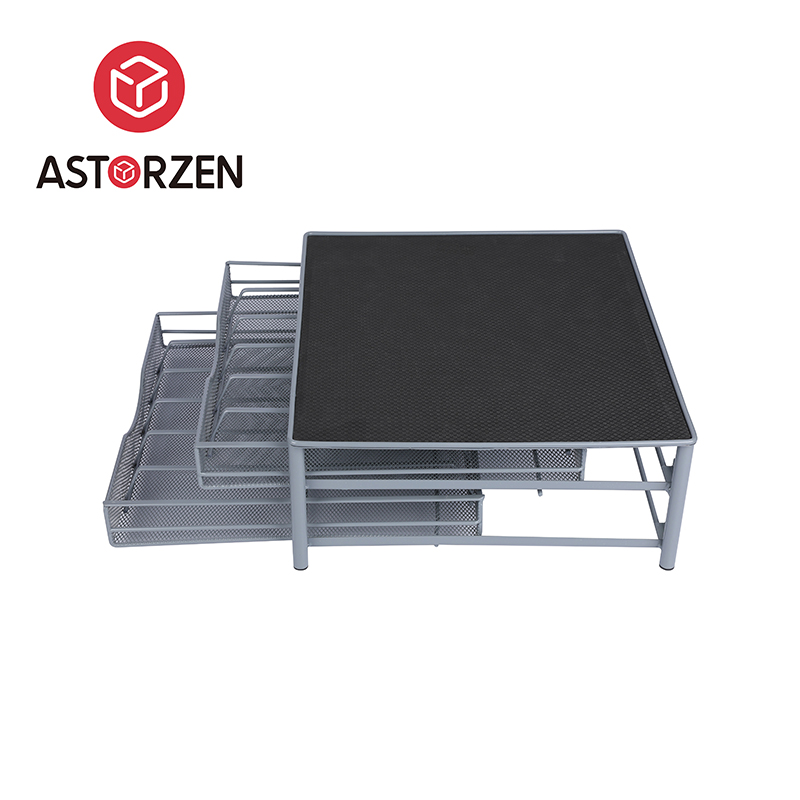

Common materials used in the production of vertical shoe racks include wood, metal, and high-quality plastics. Wood, often used in more traditional or rustic designs, offers a warm, natural aesthetic. It is also sturdy enough to handle the weight of several pairs of shoes. However, metal is becoming increasingly popular for modern vertical shoe racks because it provides a sleek, industrial look and is lightweight yet strong. Stainless steel, aluminum, or wrought iron are common choices for the framework and structure of the Modern Vertical Shoe Rack For Front Door.

In addition to the frame material, the shelving or storage components may be made from durable plastic or composite materials. These materials are often chosen for their lightweight properties and resistance to wear and tear. Some manufacturers also opt for fabric inserts or baskets to provide flexibility and improve airflow between stored shoes.

The choice of materials is a delicate balance between aesthetics, functionality, and cost. Manufacturers carefully consider the pros and cons of each material before making a decision that aligns with the overall design goals of the Modern Vertical Shoe Rack For Front Door.

Once materials are selected, the next phase involves creating prototypes of the Modern Vertical Shoe Rack For Front Door. This step is essential for evaluating the design's functionality and ensuring that the rack will work as intended.

Prototyping allows manufacturers to assess the size, strength, and stability of the shoe rack. Engineers and designers may build several versions of the rack, each one tweaking the design to improve ease of use, accessibility, and structural integrity. Prototypes are also tested for practical considerations, such as how easily shoes fit on the racks and whether the entire structure can support the weight of multiple pairs.

The feedback from the prototyping phase plays a crucial role in refining the design. Adjustments may be made to the height, width, depth, or the spacing between the shelves. Once the prototype meets all functionality and aesthetic requirements, the product is ready for production.

English

English 日本語

日本語 русский

русский عربى

عربى